Looking down the tube

Why we are gaining completely new perspectives at Gawaplast

“Looking down the tube” - an expression that stands for disappointment. “Having tunnel vision” - a metaphor for narrow-mindedness. Both images linguistically suggest that the pipe - that bulky cylinder - somehow enjoys a bad reputation.

Pipes - invisible lifelines - hold our world together. They transport fresh drinking water, provide us with energy and heat, and safely channel our wastewater. Silently and efficiently, often right under our feet. But most of us rarely stop to think about pipes.

Gawaplast, based in Neuhausen am Rheinfall, does exactly that. Dedicated to reliable plastic pipes for over 40 years, Gawaplast stands for material expertise, reliable sales and complex implementation in pipe construction, from consulting to installation. Now in its second generation, the family-run company sells, welds, and thinks in terms of pipes - and beyond.

"We recycle 100 percent of dismantled pipes and residual material."

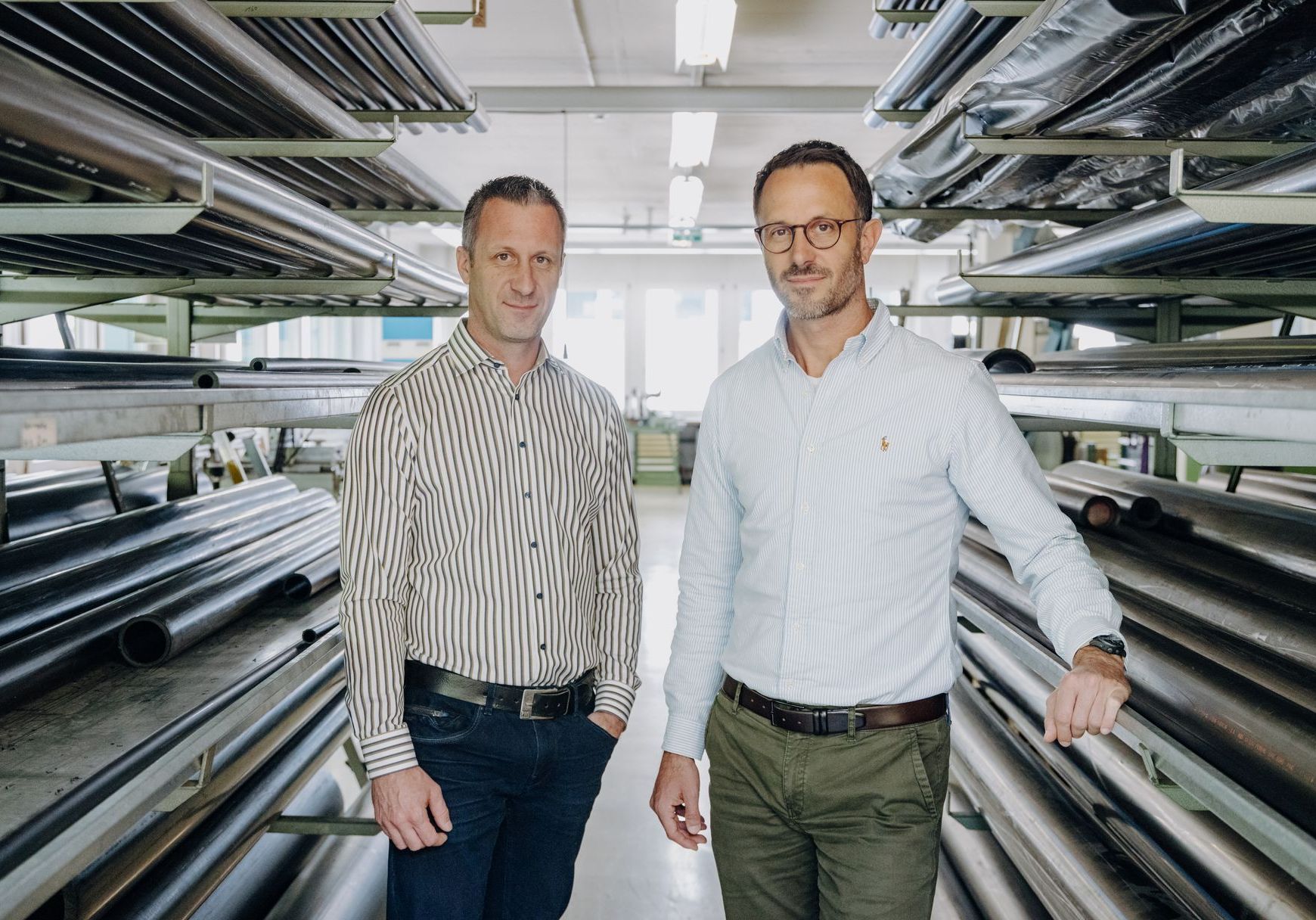

Michael and Daniel Eugster, Gawaplast AG

Together, an eye for the big picture

Brothers Michael and Daniel Eugster took over Gawaplast from their parents, Josef and Marlies Eugster, and run the company together today. They could hardly be more different from one another: one is a technically-skilled practitioner with expertise in materials and feasibility, and the other a business strategist with an eye for the big picture. Both are united by their shared background in craftsmanship and their mission to drive innovation, technical possibilities, and sustainability forward.

From concrete and wood to polyethylene

If you want to understand Gawaplast, you must lower your gaze - not out of humility, but out of curiosity. The exciting stories here are not on the surface - they begin underground. And there are a lot of stories: if you were to line up all the underground pipes in Switzerland, you would be able to circumnavigate the earth many times over.

In the past, underground pipes were made of clay or wood, then of various cast alloys. Today, the pipes in our soil are increasingly made of polyethylene (PE), a corrosion-resistant plastic. A PE pipe can remain in the ground for more than a hundred years. Their low weight facilitates transportation and installation.

PE pipes form the core of the Gawaplast range of offerings, which comprises over 10,000 items and still being expanded with new ideas. Using special proprietary welding equipment, the components can be assembled in a modular fashion, depending on the location and requirements. It's much like Playmobil, only for professionals.

Another advantage of the material: polyethylene has a low environmental impact. "We recycle 100% of dismantled pipes and residual materials," explains Michael Eugster, adding the PE pipes rarely need to be returned to the cycle at all due to their durability.

Pipes that deliver, even under extreme conditions

One of Gawaplast's biggest recent challenges came out of a success: the company was awarded the contract for the drinking water supply to the Jungfraujoch. But their high level of technical and material expertise not only won Gawaplast the contract, it also gave the company the confidence to undertake a project with extreme conditions: an altitude of 3,455 meters, steep terrain, at temperatures as low as -32 degrees, at night, in railroad tunnels.

This extreme task goes unnoticed by the thousands of tourists who make the pilgrimage to the Jungfraujoch by train every day. At the top, drinking water and toilet facilities are taken for granted. But until 2010, huge quantities of water were transported up from Kleine Scheidegg in cistern trucks - a logistical feat that today (and probably in a hundred years' time) will be handled by pipe systems planned and installed by Gawaplast. If you look at the tunnel floor next to the railway tracks, you can even see them: pipes that make the impossible possible.

What is it like creating something that is so crucial, and get goes unnoticed? Michael and Daniel Eugster shrug their shoulders. "We are part of a proud and well-connected industry," they say. "We know why we get up every day: Gawaplast stands for reliability. Anyone who orders from us gets exactly what they need. Whether it's a standard range or custom-made products, we do everything we can to make sure it works. Fast, precise, reliable - that's more important today than ever." The brothers agree on this, and keep their successes, just like their products, below the surface.

There is more

Schaffhausen newsletter

New to Schaffhausen or been here awhile? Stay up to date with our newsletter!

Welcome to the area for makers - you'll be hearing from us soon with exciting updates from Schaffhausen.

An error has occurred, please try again.